The Taffy Wrapper Cam Mechanism: A Key Innovation in Candy Packaging

- Breno Cruz

- 8 de fev.

- 2 min de leitura

Introduction

The confectionery industry relies heavily on automation to ensure high-speed and efficient packaging. One of the essential mechanisms in candy wrapping machines is the Taffy Wrapper Cam Mechanism, which enables the precise and consistent twisting of candy wrappers. This article explores its working principles, components, applications, and benefits in modern packaging systems.

Working Principle

The Taffy Wrapper Cam Mechanism transforms rotary motion into oscillating or reciprocating motion, which is necessary for twisting the ends of candy wrappers securely. The operation of this mechanism follows these fundamental steps:

Rotary Input: A motor or drive system generates a continuous rotary motion.

Profiled Cam Action: The cam, designed with a specific profile, interacts with a follower arm.

Follower Movement: The follower arm moves in response to the cam's shape, creating an oscillating or reciprocating motion.

Wrapper Twisting: The oscillatory motion is transmitted to gripping elements (such as rollers or grippers), which rotate and twist the ends of the wrapper.

Completion and Release: Once the required number of twists is achieved, the candy is released, and the cycle repeats.

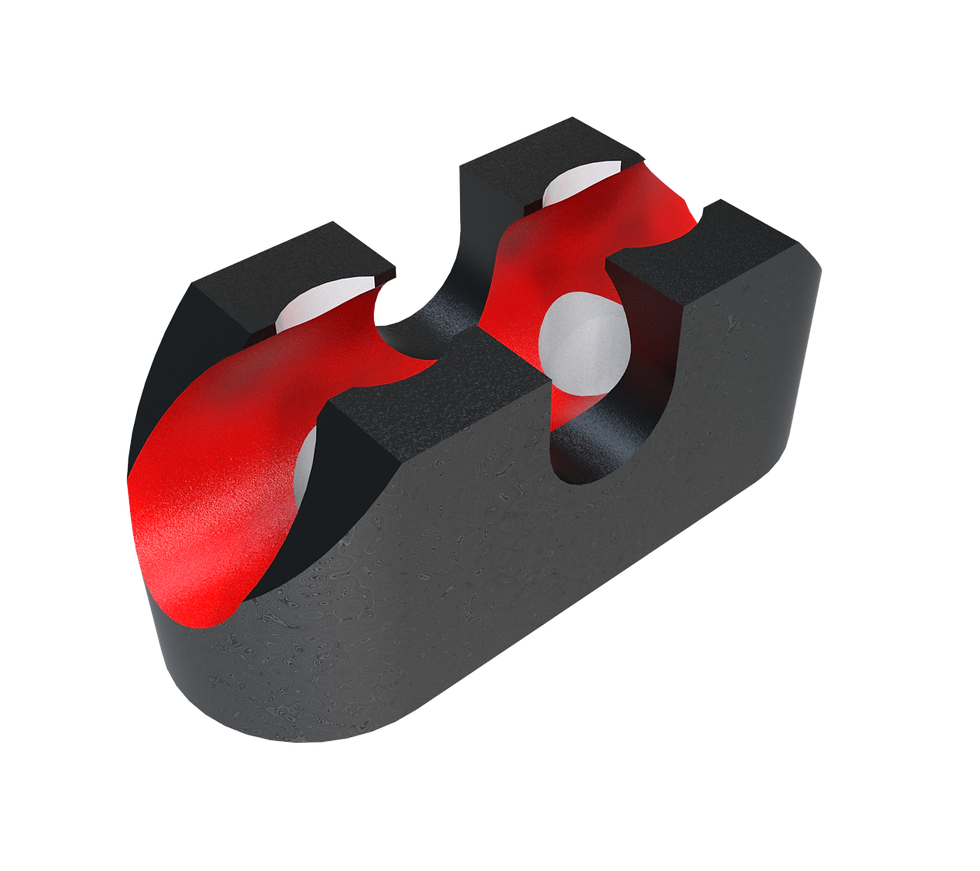

Components of the Mechanism

The Taffy Wrapper Cam Mechanism consists of several critical components:

Cam: A precision-machined component with a defined profile to guide the follower's motion.

Follower Arm: Moves in response to the cam's shape and transmits motion to the wrapper-holding elements.

Grippers or Rollers: Hold the candy wrapper and execute the twisting motion.

Drive System: Typically an electric motor or belt-driven system providing the primary rotary input.

Synchronization System: Ensures that each candy wrapper receives the same level of twisting and packaging precision.

Applications

This mechanism is widely used in various industrial applications, including:

Candy and Chocolate Wrapping Machines: Ensures efficient and uniform twisting of wrappers in high-speed production lines.

Pharmaceutical Packaging: Used in wrapping certain medical tablets or lozenges requiring twisted packaging.

Automated Food Packaging Systems: Applied in wrapping small food products that require secure closures.

Benefits of the Taffy Wrapper Cam Mechanism

High-Speed Operation: Allows rapid packaging of candies without compromising quality.

Consistent Wrapping Quality: Ensures uniform twisting, improving product presentation and sealing.

Reduced Manual Labor: Automation eliminates the need for hand-wrapping, increasing efficiency and reducing costs.

Versatility: Can be adapted for different wrapper materials and product sizes.

Reliability: Designed for continuous operation with minimal maintenance.

Conclusion

The Taffy Wrapper Cam Mechanism plays a crucial role in modern packaging, particularly in the confectionery industry. By converting rotary motion into precise oscillatory movements, this mechanism ensures efficient and uniform candy wrapping at high speeds. Its reliability and efficiency make it an indispensable component of automated packaging lines worldwide.

Comentários